The chapter outlines a series of steps that can be followed to implement ABC. A case study is used to demonstrate ABC and its impact on the decision process. Manufacturing overheads are allocated to each department at $500 per direct labor hour worked. Assume $10,000 worth of pigments and resins are introduced in pigment dispersing department as direct materials. Texas Monthly reports that Sandy found a way to write unapproved checks in the accounting system.

Direct Labor Costs

It is difficult to tell the first drumstick made on Monday from the 32,000th one made on process cost system Thursday, so a computer matches the sticks in pairs based on the tone produced. Consistency in the cost accounting process is vital for ethical considerations. Changes to the cost accounting process should be made with caution and transparency to avoid any ethical concerns.

The Role of Labor

Maria sees this as an opportunity to enter a niche market for busy families or individuals who want home-cooked meals with a variety of options and combinations, but who have little time. Maria already has an expansive deli, bakery, and prepared foods section in the store and sees this opportunity as a viable option to increase sales and its customer base. With meals to go, customers can choose from an array of options and can indicate the quantity of each item and the time of pickup. The customer simply pulls up in a designated spot at Maria’s and the food is brought to their car, packaged, and ready to take home to enjoy. We’re a headhunter agency that connects US businesses with elite LATAM professionals who integrate seamlessly as remote team members — aligned to US time zones, cutting overhead by 70%. If a worker incurs 3 hours of time working on batch number 112, the gross wages have to be reclassified from labor control to work-in-process.

What Are the Key Factors to Consider When Selecting a Process Costing Method for Your Manufacturing Process?

While the service industry does not produce physical products, it can use process costing to calculate the cost of services. Service providers can break down the production process into individual steps and assign costs to each step to calculate the service cost. The FIFO method involves calculating the cost of production based on the order in which materials are consumed in the production process. Under this method, the cost of the oldest materials is allocated to the first units produced. The cost of the newest materials is allocated to the most recently produced units. Several process costing methods are used in manufacturing, including standard cost, weighted average, and first-in, contra asset account first-out (FIFO).

Process costing Process cost accounting

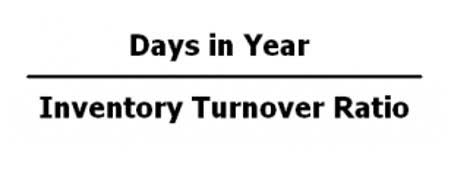

Accountants compute the cost per unit by first accumulating costs for the entire period (usually a month) for each process or department. Second, they divide the accumulated costs by the number of units produced (tons, pounds, gallons, or feet) in that process or department. Direct costs, on the other hand, can easily be traced to specific products or services.

Hannah – Process Costing System

- Several process costing methods are used in manufacturing, including standard cost, weighted average, and first-in, first-out (FIFO).

- Then the Packaging Department transfers the products to Finished Goods Inventory.

- The organisation can use this method to identify the relevant costs (i.e., direct and indirect costs) for each process, and no abnormal expenses are charged to any process.

- This can be challenging, especially if the company has legacy systems or multiple systems that need to integrate more easily.

- Coca-cola is a carbonated drink bottling company that specializes in unique flavors.

- In these situations, process costing can provide an accurate calculation of the cost of production per unit.

- As one of the process costing system examples, let’s look at a supposed company, ABC Inc, that produces wire rods, that pass through multiple production departments.

It is a crucial tool for manufacturers to calculate costs accurately and make informed pricing, inventory management, and profitability decisions. Process costing is suitable for industries where the product is continuous and the end products are https://www.bookstime.com/articles/employment-contracts-for-small-businesses identical. In such industries, the production cycle is standardized & even the quantum of the normal loss of inputs & outputs is quantified earlier.

What is Process Costing? Features, Types, Advantages & Limitations, Process

This method is helpful for companies that make products with varying prices, as it allows for a more accurate representation of the actual production costs. In summary, process costing is a critical element in manufacturing, and businesses that implement it effectively can achieve significant benefits. Companies can maximize their resources, reduce costs, and increase efficiency by taking a comprehensive and strategic approach. Before implementing a process costing system, developing a detailed plan outlining the objectives, processes, and resources required before implementing a process costing system is essential.

1 Process Costing Vs. Job Order Costing

An activity is a unit of work, task, or event that has a specific purpose, such as setting up a machine or operating a machine. The most common cost objects are the products or services that a company sells. Other cost objects include customer service calls, product rework activities, product design projects, suppliers, and customers. When the boat is sold, management can tell exactly how much money the company made or lost on that unique product.

This will require the use of the equivalent unit computation, and management selects the method (weighted average or FIFO) that best fits their information system. The textile industry uses process costing to calculate the cost of producing fabrics. This industry produces fabrics in large quantities with a consistent manufacturing process, making process costing an appropriate technique. The chemical industry uses process costing to calculate the cost of producing chemicals.